Success story

IoT-enabled vertical farming platform

A graph illustrating yield growth before and after implementation

The challenge

A global industrial company with a well-established sustainable vertical farming business needed a digital backbone to scale operations. Their farms required precise control of the microclimate — including temperature, humidity, lighting, and irrigation — and seamless integration of thousands of IoT devices. Existing tools couldn’t ensure the level of scalability, real-time insight, and automation required for international growth.

Our solution

We built a comprehensive IoT and AI-driven platform, combining cloud infrastructure, advanced sensors, and user-centric design:

- Sensor integration — connected hygrometers, air and soil thermometers, chemical soil sensors, weather stations, and hydraulic flow monitors.

- Multi-channel data transmission — IoT devices streamed data via LoRa, ZigBee, WiFi, Thread, and Bluetooth to local nodes and the cloud.

- AWS serverless architecture — ensured real-time processing, analytics, and scalability for global farm networks.

- AI-powered insights — computer vision from drones and satellites detected anomalies in crop growth, improving decision-making.

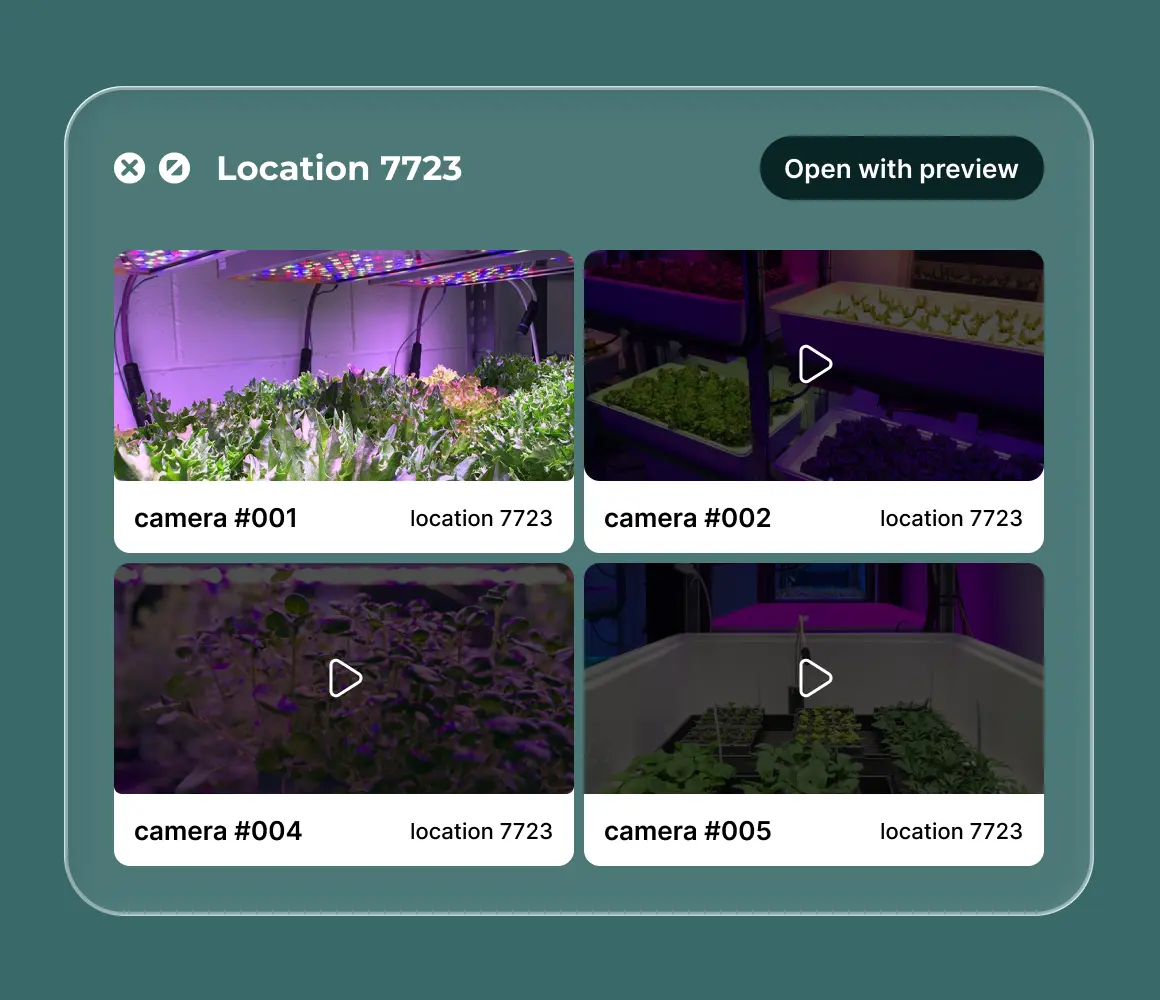

- Unified dashboard — a web-based and mobile-friendly platform allowed operators to monitor conditions, receive alerts, and adjust critical parameters instantly.

The results

+40%

crop yields through data-driven optimization of growing conditions.

-70%

water usage thanks to precise irrigation monitoring and scheduling.

Energy Efficiency via adaptive, spectrum-optimized lighting systems.

Scalable Growth with a flexible architecture that supports the rapid deployment of new farms worldwide.

Resilient Sustainability through reduced resource consumption and higher reliability in food production.

Why DFG

What made this project a success was the vision-driven approach. At DFG, we bridge IoT, AI, and enterprise-scale systems into solutions that automate processes and redefine what’s possible. We design platforms not only to work today, but to scale and evolve with tomorrow’s demands.

For this client, we went beyond digitalization of the greenhouses. We built the foundation for a global sustainable food system — one that proves technology can serve both profit and planet.

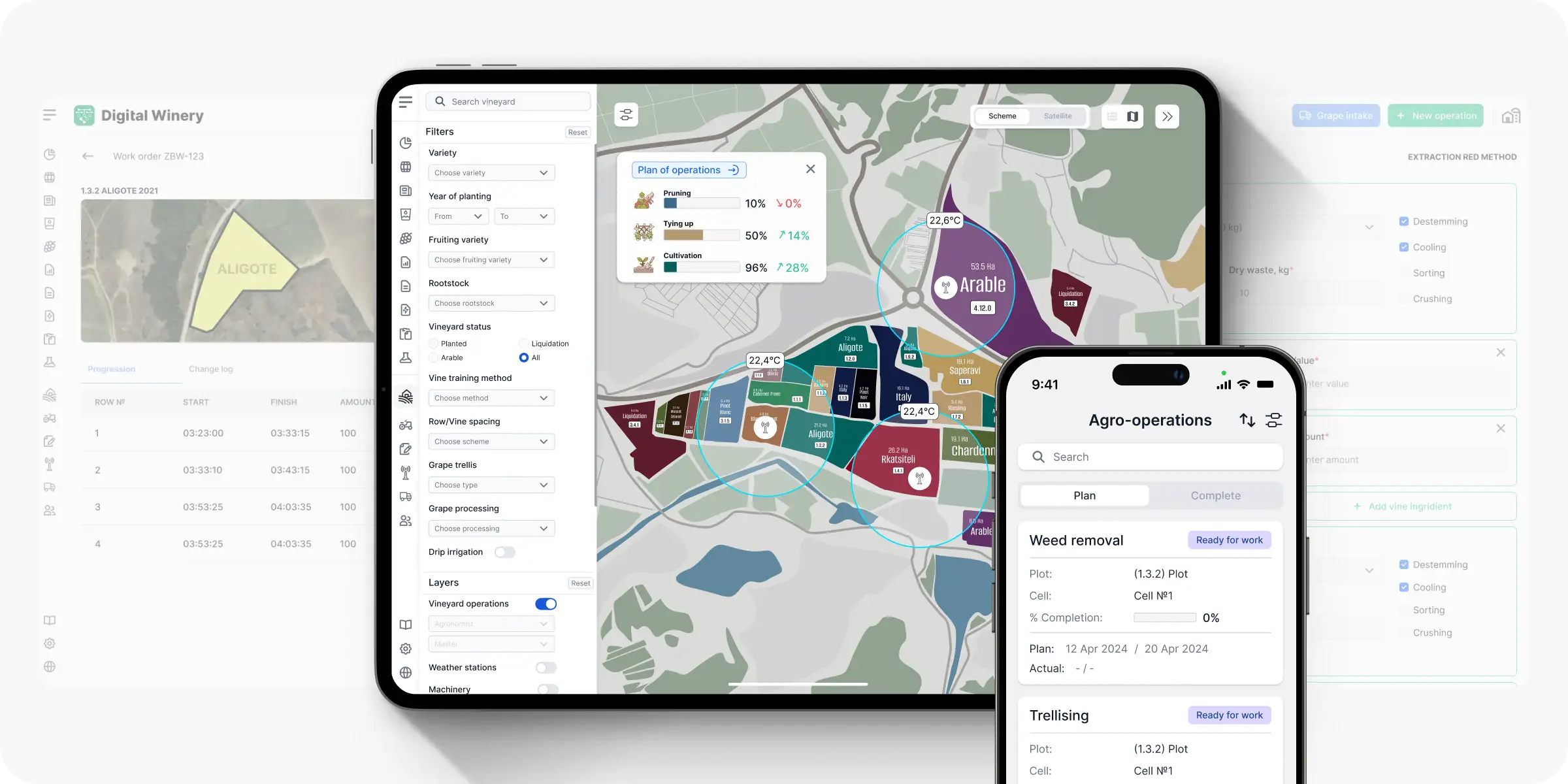

Beyond vertical farming: applying it across AgriTech

The same digital framework can transform any AgriTech business:

- Vineyards & wineries — monitor soil moisture, predict disease risks, and optimize irrigation across hectares of vines.

- Greenhouse operations — automate climate control, nutrient dosing, and energy management for consistent crop quality.

- Open-field farming — combine IoT data with satellite imagery to optimize yield forecasts and reduce input waste.

- Agri-logistics & storage — track freshness, humidity, and temperature of produce in transit to minimize losses.

Wherever nature meets scale, DFG delivers the digital intelligence layer that enables sustainable growth.